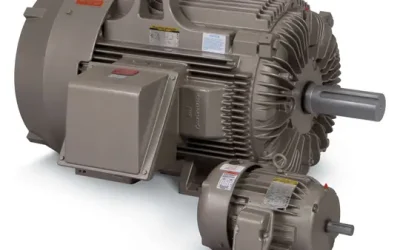

Electric motors are an essential component of many industries, from manufacturing to transportation. In Connecticut, the demand for reliable and efficient electric motor performance is ever-growing. This is where Electric Motor Rewind in Connecticut services come into play, offering a crucial solution to maintain and enhance motor functionality.

Understanding Electric Motor Rewind

Electric motor rewind services involve the process of refurbishing the motor’s coils, which can deteriorate over time due to wear and tear. This service is vital for restoring the motor’s efficiency and extending its lifespan. Rewinding is often more cost-effective than replacing an entire motor, making it a preferred choice for many businesses.

Benefits of Electric Motor Rewind

- Cost Efficiency: Rewinding can significantly reduce expenses compared to purchasing a new motor. This is particularly beneficial for large motors where replacement costs can be prohibitive.

- Extended Lifespan: By replacing the worn-out windings, the motor’s operational life is extended, ensuring prolonged service and reliability.

- Improved Performance: A rewound motor can perform as efficiently as a new one, if not better, especially when modern materials and techniques are applied during the process.

- Environmental Impact: Opting for a rewind instead of a replacement reduces waste and the environmental footprint associated with manufacturing new motors.

Process of Electric Motor Rewind

The rewinding process is meticulous and involves several steps to ensure the motor is restored to optimal condition:

- Disassembly: The motor is carefully disassembled to access the windings.

- Inspection: The motor components are inspected for damage or wear.

- Cleaning: All parts are thoroughly cleaned to remove dirt, oil, and debris.

- Rewinding: New coils are wound using high-quality materials tailored to the motor’s specifications.

- Reassembly and Testing: The motor is reassembled, and rigorous testing is conducted to ensure performance meets or exceeds original specifications.

Choosing the Right Service

When selecting an electric motor rewind service in Connecticut, consider the following:

- Experience and Expertise: Opt for services with a proven track record and experienced technicians who understand the intricacies of motor rewinding.

- Quality of Materials: Ensure the service uses high-grade materials to guarantee the longevity and efficiency of the rewind.

- Testing and Quality Assurance: Choose a provider that offers comprehensive testing and quality assurance protocols to confirm that the motor performs optimally post-rewind.

For more information on electric motors and services, check out Electric Motor Rewind Connecticut.

Electric motor rewind services in Connecticut offer an invaluable solution for industries relying on motors for their operations. By choosing to rewind rather than replace, businesses can enjoy cost savings, enhanced performance, and contribute to environmental sustainability. Whether dealing with motors in manufacturing plants or transportation fleets, understanding and utilizing these services can lead to significant long-term benefits. As technology advances, the methods and materials used in rewinding continue to improve, ensuring that motors remain an efficient and reliable part of industrial operations for years to come.