Block bearing problems can compromise the operational efficiency of your system. Knowing a few tips and tricks on how to keep those bearings in tip-top shape can come in handy and keep you from ordering premature replacements for pillow block bearings in Texas:

Know how they work

The more knowledgeable you are about bearing types, functions, properties and designs, the better your buying decisions will be. Understanding how bearings work will help you determine major considerations and problems along the way.

Apply lubrication

Some people forget about that bearings require lubrication to function at optimum levels. Be sure to keep your bearings supplied with the proper lubrication.

Check the oil

The oil must be clean and free of contaminants and dirt. It can be disastrous for your systems if dirty oil finds its way into your bearings. Be sure to check the quality of the oil before you use it. That’s going to spare you plenty of problems in the future.

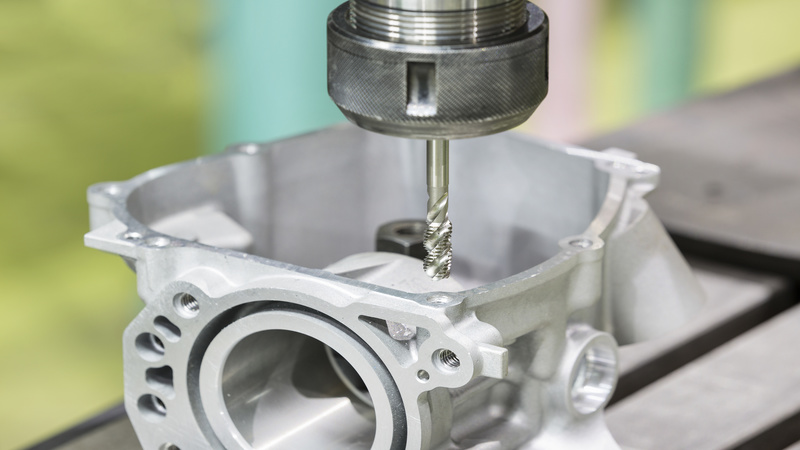

Avoid handling or mounting mistakes

High-quality bearings are typically durable and so stays operational for a long time. However, errors in mounting or handling could easily lead to long-lasting damage and premature failure.

Monitor heat levels

It won’t be long before your system is affected once your bearings are exposed to abnormal heat levels as well. Be sure to keep an eye on your temp controls. Otherwise, you’ll find yourself getting replacements much, much sooner rather than later.

Go for reliable suppliers

Buying pillow block bearings in Texas from reliable suppliers is a great preventive measure. Cheap bearings are unlikely to hold up to the strain and stress. By ordering from suppliers with a reputation for delivering quality components, you know you’re getting the best components around, ones that will work better and last you longer.